A Good Project and the Unpleasant Surprise

The trade show is over, the booth was a success, and the meetings went well—everything seems to have run according to plan. But then, often weeks later, comes the surprise: the logistics invoice for the trade show is significantly higher than expected. The previously smooth-running project suddenly leaves a bitter aftertaste.

This situation is no longer an exception. Both exhibitors and booth constructors increasingly report unexpected subsequent charges that are difficult to communicate after the project is completed. The issue is not isolated mistakes, but a structural problem: the costs of show logistics have become increasingly unpredictable and are slipping out of participants’ direct control.

What Does Trade Show Logistics Mean, and Who Is Responsible?

Trade show logistics, also called on-site logistics, includes all logistical services around setup and dismantling on the exhibition grounds, such as:

- Unloading trucks

- Provision of equipment like forklifts

- Transporting booth components to and from the booth location

- StorageStorage refers to the temporary warehousing of materials, packaging, exhibition equipment, or other items that are needed—or not immediately needed—during booth setup, the exhibition itself, or after dismantling. This can include packaging materials, spare parts, or additional exhibits stored near the booth, as well as the storage of larger booth components, furniture, or promotional materials in an external warehouse. of full goodsFull goods refers to valuable items and equipment that are still filled or functional, which are not needed at the booth but must be stored securely during the trade show—such as tools, ladders, lifting equipment, or machines. During the exhibition period, full goods are stored by a freight forwarder or the trade show logistics provider. As a rule, the trade show logistics provider assumes liability during storage, as these items are stored with insurance coverage.

and emptiesEmpties refers to empty packaging, transport aids, and materials that are no longer needed after the booth has been set up (e.g., empty crates, pallets, bubble wrap, packing material). During the trade show, these empties are stored by a freight forwarder or the trade show logistics provider and are returned to the booth after the show ends.

No liability is assumed in case they are damaged or lost. - Coordination of delivery time slots

- Waste disposal

Important: The logistics service providers are specified by the organizer. Exhibitors or booth builders are not allowed to hire alternative providers—third parties are not permitted.

Experienced booth builders typically handle all the organization and communication of these services for their clients. Billing for on-site logistics, however, typically occurs after the event—sometimes with weeks of delay. Reliable pre-calculation? Nearly impossible.

Uncertainties in On-Site Logistics

Delivery

- Slot booking

- Waiting times

- Missed time windows

Transport

- Forklift charges by time

- Inexperienced drivers

- Delays

Build Phase

- Interim storage of empties

- Extra trips due to lack of space

During the Show

- Last-minute changes

- Spontaneous extra deliveries

Dismantling

- Forklift and return transport bottlenecks

- Double time charges

Storage Removal

- Storage costs calculated in cubic meters

- Rounding up smaller volumes

Real-World Perspective: When Minutes Count Double

“Ten more minutes and suddenly… double the cost.”

For a medium-sized booth, we realistically planned one hour each for forklift use during setup and dismantling. But during setup, the driver was inexperienced and took 1 hour and 10 minutes—invoiced as 2 hours. During dismantling, the driver was better, but the aisles were blocked—this time, 1 hour and 5 minutes, again billed as the full 2 hours.

Bottom line: Even though we included a buffer in our calculations, the final bill was almost twice as high. For us, it was barely understandable—for our client, not at all.

— Maren Förste, Customer Support at WUM

- Planned costs 55%

- Actual costs 100%

Often no way through for forklifts

Why Logistic Costs Are Hardly Calculable Anymore

Unlike other show costs like materials and personnel, logistics expenses are difficult to estimate in advance due to lack of transparency and reliability.

Key factors making calculation difficult:

- Guest Events – When grounds are rented to external organizers, higher rates can be imposed due to additional intermediaries.

- Time-Based Billing – Many services (like forklift transport) are billed by every begun hour—work taking 1:05 h is billed as 2 h, nearly doubling the cost.

- Staff Shortages – Inexperienced staff cause slower processes and higher costs.

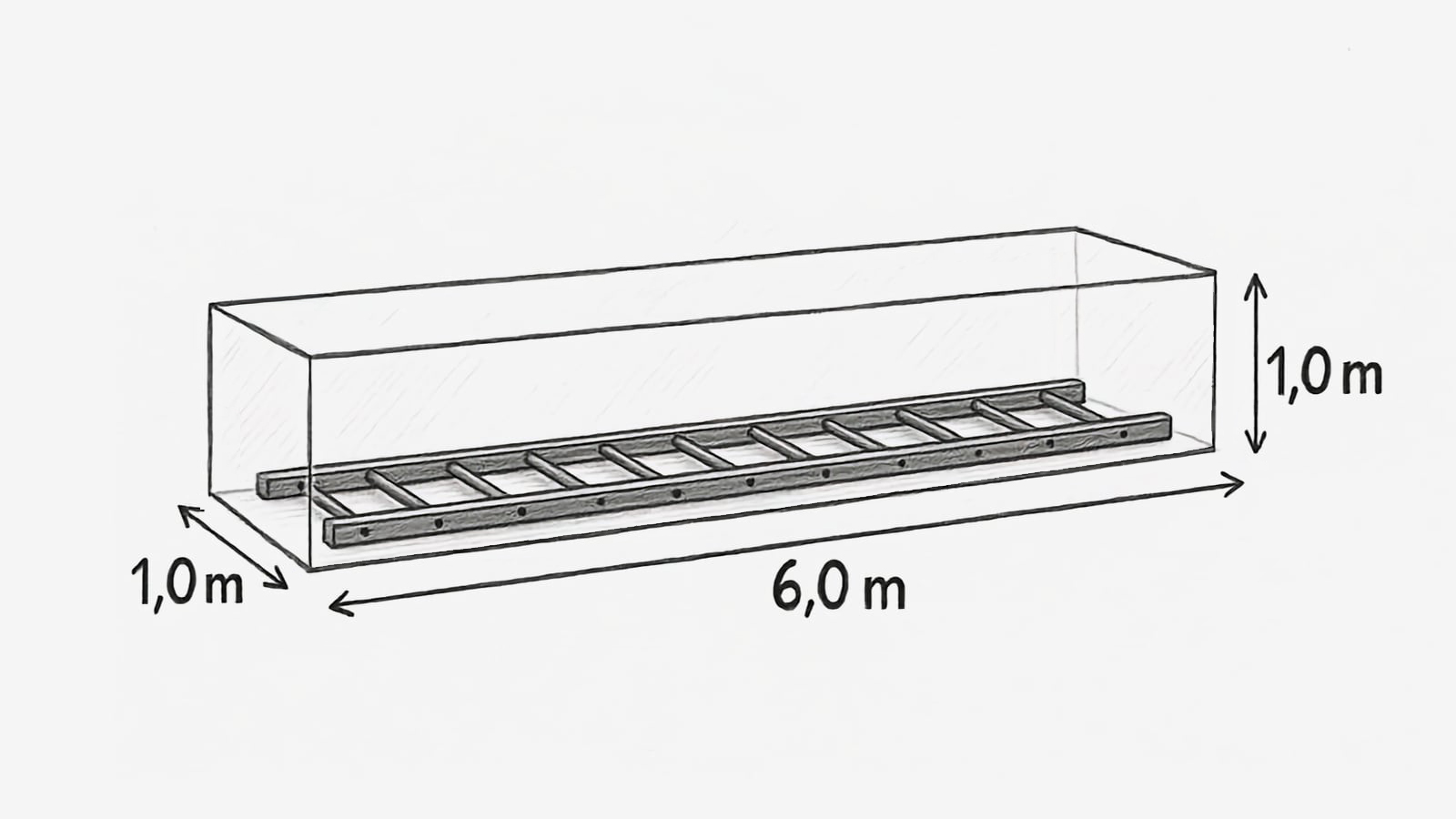

- Volume rounding in storage – full goods and empties: storage is calculated based on volume (with the height always rounded up to at least 1 m³). This means, for example, a single 6-meter ladder, which would actually only take up 0.3 m³ (6 x 0.5 x 0.1 m), quickly becomes a full-goods volume of 6 m³ (6 x 1 x 1 m).

- Service Charges – Each ordered service comes with an additional fee per transaction.

- Weekend surcharges – Costs increase on weekends. Short-notice, unplanned tasks—such as the additional delivery of an exhibit on the weekend—can quickly lead to unforeseen extra expenses.

The result: Even with good planning and an experienced booth builder, deviations that exceed double the original amount are no longer uncommon.

Real-World Perspective: The Problem with Volume-Based Billing

“From a stack to a bottomless pit.”

We had conservatively calculated the storage costs for a guest event at a renowned exhibition venue. But the external organizer applied their own rates—almost three times higher than expected.

On top of that: every single small item (we had several things that needed to be packed separately) was rounded up to 1 m³. So 0.2 m³ became 1 m³—and that happened five times. In the end, 8 m³ appeared on the invoice, even though in reality only just under 3 m³ were stored. How are you supposed to explain that to your customers?

— Marcel Maier, Operations Manager at WUM

- Planned costs 38%

- Actual costs 100%

Rounding up volumes in storage often causes higher costs

Three Billing Models for Maximum Transparency

To address these uncertainties, some booth builders like WUM offer three transparent models for dealing with unpredictable on-site logistics costs:

Three WUM Billing Models:

- Direct billing via the logistics partner

The assignment is carried out by WUM with a power of attorney—the invoice is sent directly to the exhibitor. - Billing via WUM with handling-feeHandling fees (also called handling flat rate, handling charge, or simply processing fee) generally cover the coordination, administrative, and consulting efforts of the service provider.

WUM pays the service provider and invoices the customer/exhibitor for the costs with a 15% handling surcharge. This includes invoice verification and proof of expenditure. - All-Inclusive Model with Safety Margin

The calculation is based on experience, especially from the previous year. A safety margin is added to the calculated average value. This way, the agreed flat rate remains binding—no matter what happens. Ideal for exhibitors with a fixed budget.

Which Billing Model Fits Which Customer?

| Modell | Transparency | Cost Predictability | Cost Overrun Risk | Recommended for… |

|---|---|---|---|---|

| Direct billing via logistics partner | High | Low | High | Clients experienced in negotiating and reconciling supplier bills |

| Billing via WUM with handling fee (15%) | High | Low | High | Clients appreciating service and double-checking |

| All-inclusive flat rate (+safety margin) | Limited | High | None | Clients needing 100% cost certainty/fixed budget |

What Booth Builders Can Do—and What They Can’t

Exhibition stand construction companies like WUM have extensive experience in planning and execution. They offer transparent advice, assist with organizing logistics, and check invoices for plausibility.

What WUM Customers Can Rely On:

- RProvide early guidance and education

- RPlan and pack efficiently

- ROffer transparent billing models

- RCheck invoices for plausibility

- OChoice of logistics partner is dictated by the trade show organizer

- OInfluence on operational aspects and billing is limited

Conclusion: Acting Early Protects Against Surprises

On-site logistics remain a risk factor in trade show planning, affecting both exhibitors and booth builders. Addressing it early increases chances of avoiding budget overruns.

Five-Point Plan for Exhibitors

- Include on-site logistics!

Plan for unexpected extra charges in your budget. - Discuss early!

Talk through logistics plans with your booth builder. - Pick the right billing model!

Choose the approach that best fits your project. - Minimize last-minute extras!

Short-notice requests can sharply increase costs, especially with weekend work, surcharges, extra storage, and equipment rental.

(Example: An exhibit needs to be delivered to the trade show at short notice—and the delivery can only take place on the weekend. This means that, in addition to the “normal” extra charges, there are immediately higher costs due to weekend surcharges for labor, storage, forklift rental, etc. In such cases, costs can quickly multiply.) - Involve your booth builder!

Let them check invoices—they have the expertise.

Logistics are an integral part of every trade show, but non-transparent on-site logistics can become a budget breaker. An open conversation and proactive planning before the event are the best way to avoid having to justify yourself after the show.

Talk to your booth constructor in good time—so your trade show is not only a visual, but also a financial success.